Is your ATK heel unit tough to rotate? This easy maintenance tip—the re-greasing of the lateral release spring—might be the fix you need.

Luck has been on my side. Over the years, I’ve had a few problems with tech bindings. There was the used pair of LT Turns I purchased with too much play in the heels and the scary toe unit pre-release I had a few years back while jump turning on skittery ice—user error, I was hasty and didn’t clear ice from the toe inserts.

Other than that, tech bindings have been golden. Here at THR, we all have our preferences for tech bindings. There are Ski Trab fans, a Dynafit Expedition TLT worshiper, Plum 170 devotees, and those who lust after ATK bling.

Most of my skis have ATK Crest 10 or Haute Route bindings. A beloved pair of Zero G 95s sport Plum R-170s, and I swear, there is no issue turning the heels; they swivel/rotate and snap into place. This brings us to discuss heel units in more detail, specifically ATK heel units.

On Sunday, during a glorious Central Oregon day calling for a big effort, I could barely hand-rotate my ATK Haute Route heel units while transitioning between skiing and skinning. I purchased these bindings from Black Diamond rouglhy four years ago; they are rebranded as BD Helio 200s. These bindings have been mounted to Movement Alp Track 100s, DPS Pagoda Tour 112 RPs, and some BD Cirque 84s. (I maintain a heel unit mount plate on the DPS and BD skis to save a few dollars and swap the heel units back and forth. If it is 112mm underfoot season, it is not 84mm underfoot season.

For real…I’ve never, ever, ever, ever, had any issues with these ATKs until Sunday. Then, with no warning, rotating the heels felt like trying to break a lightly seized bolt. Rotating was possible, but I had to remove my ski, stand the ski on its tail, grab the ski’s mid-section with my left hand, secure the heel unit with a gloved right hand (I was unable to rotate with a bare hand: I’m delicate), channel my inner Popeye, and turn 180-degrees from flat to pins-forward.

On Monday morning, back home, I tried to rotate the heels to ensure it hadn’t been just a tech-binding nightmare. I got the same result, which was the same high-friction rotations.

Ten minutes later, I’m on Skimo.co ordering ATK binding grease. Here we are on Wednesday afternoon, and the miracle that is USPS Priority mail has me converting the kitchen table into a ski bench.

If you, too, experience an ATK heel unit rotating stubbornly, the fix should be easy. We’re here to lubricate the heel’s lateral release system—which is much easier done than it sounds.

The fix should work on any ATK unit with an adjustable lateral release. This includes ATK bindings in the Free Touring, Touring, and Speed Touring lines. For the record, I likely could have used high-quality bike grease, but you know…warranties. For now, it’s only smooth-turning heel units. Here’s how it happened.

The Tough-to-Rotate Heel Unit (turn up the volume for full effect)

Process to Lubricate ATK Heel Unit Lateral Release Spring

Step 1: Set the ski on a flat surface.

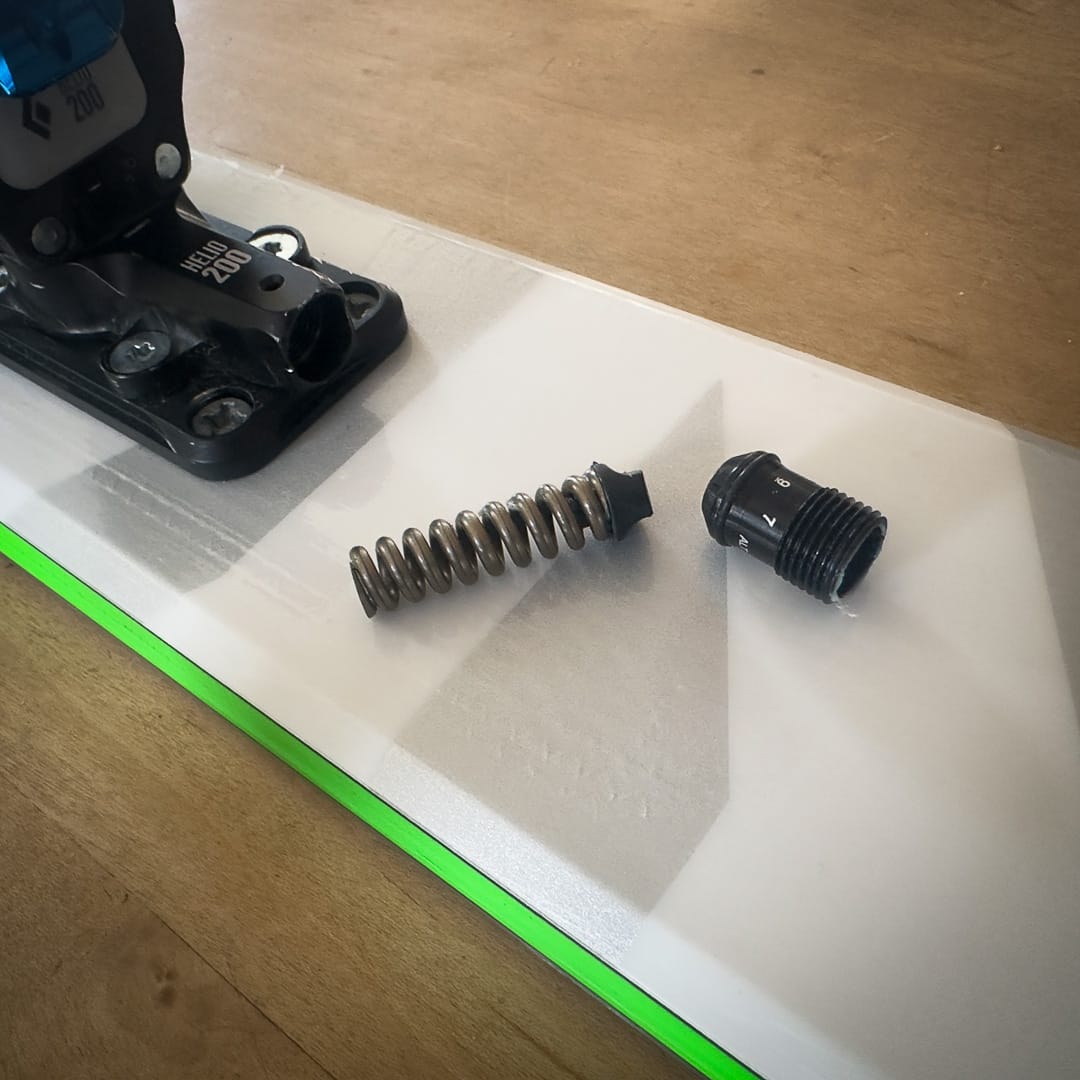

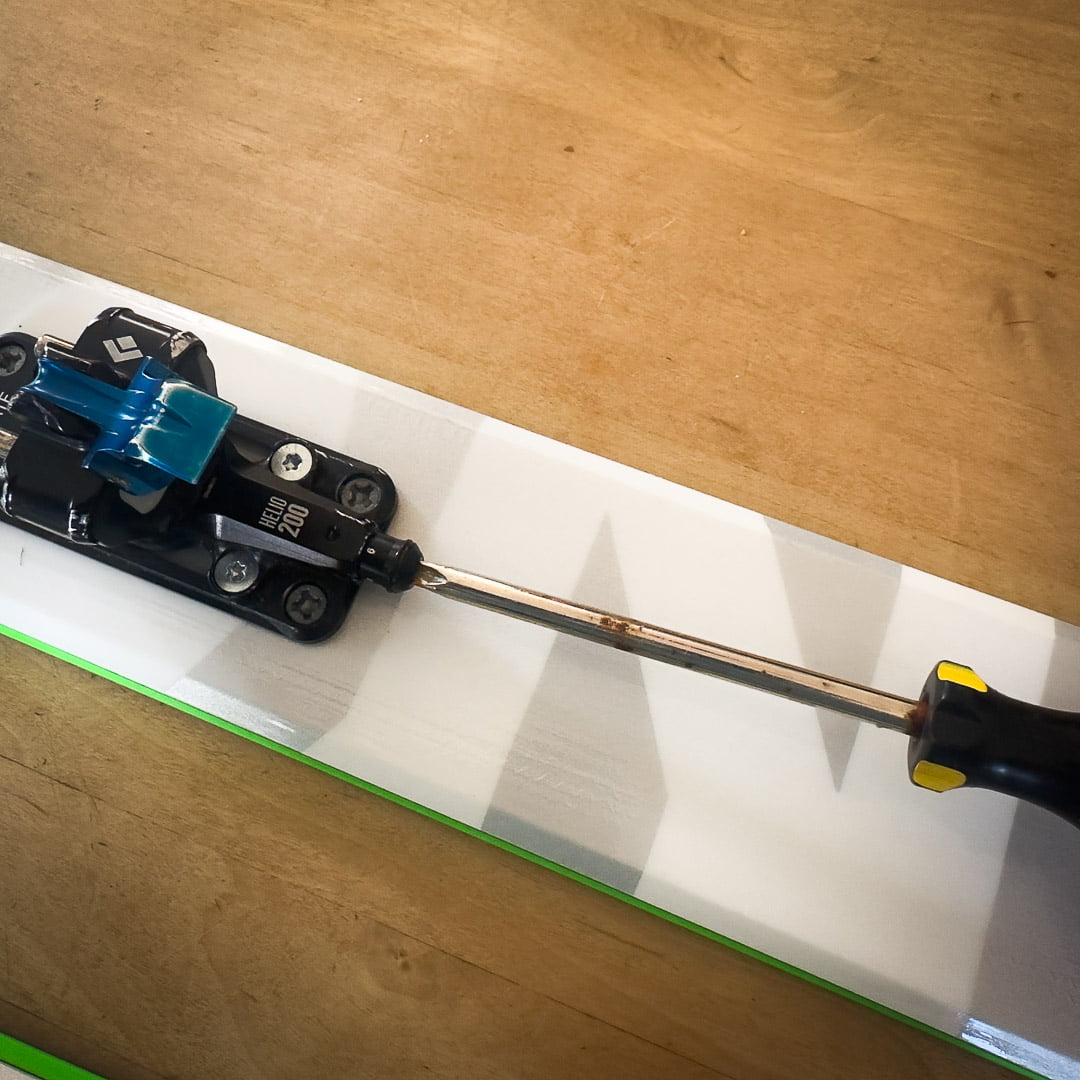

Step 2: Use a Phillips screwdriver to loosen and remove the spring cap and spring. The heel unit will/should swivel freely.

Step 3: Clean/remove any grit/dirt from the tension spring and cap with a damp cloth, and then dry.

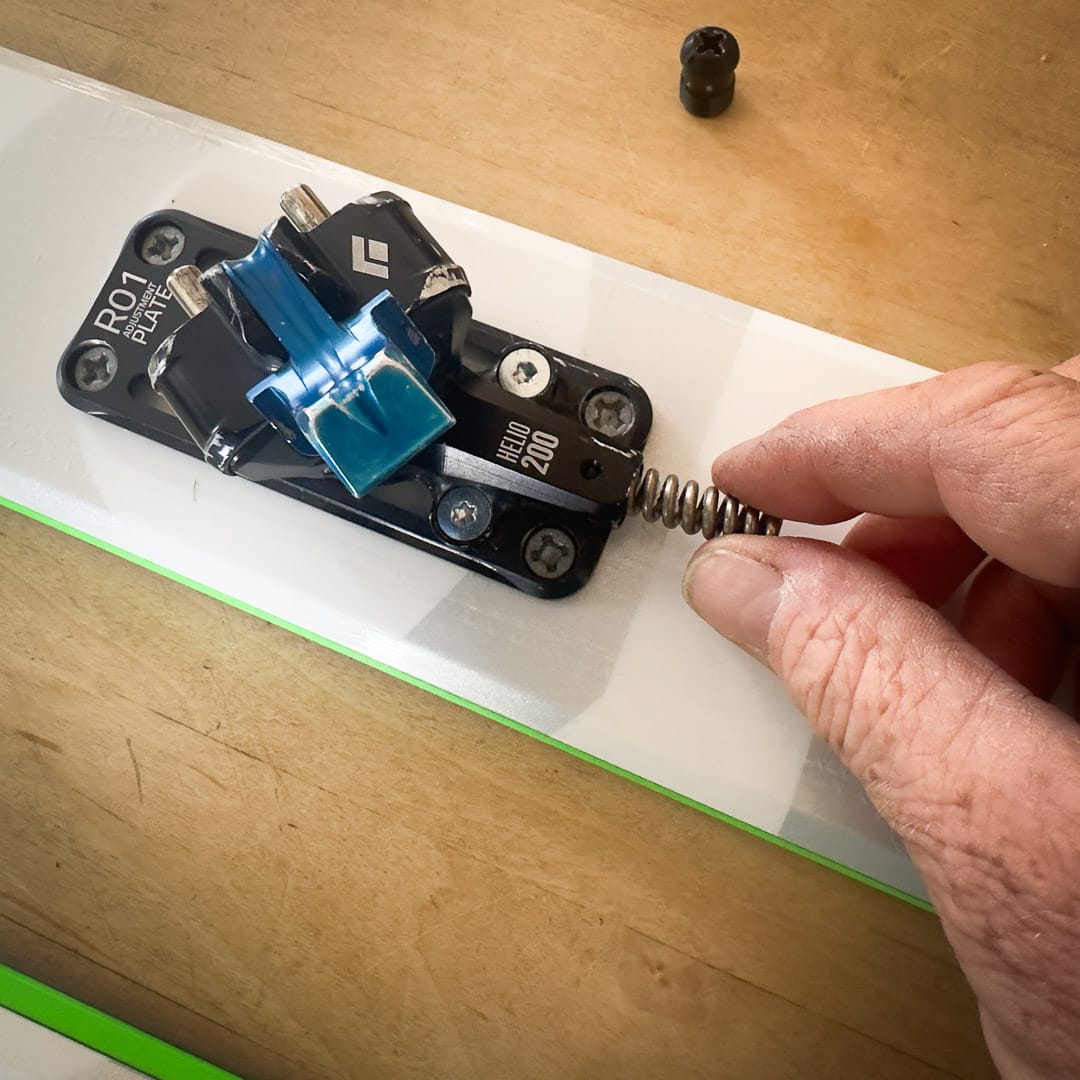

Step 4: Apply a small amount of binding grease to the spring head (the end of the lateral release spring inserted into the heel unit).

Step 5: Insert the spring in the correct orientation (head first), insert the spring cap, and retighten with a screwdriver to the proper lateral release setting.

Step 6: Rotate the heel unit several times. The heel should rotate more easily.

The Post-Greased EZ-to-Rotate Heel Unit

Step 7: There’s a video from ATK too.

Leave a Reply

You must be logged in to post a comment.