In spring 2020, perhaps the worst timing in modern history to launch a new company, MADE Outdoor opened its doors. The concept, perhaps not unique in the formal wear world, is a revolutionary step in the world of outerwear. Custom, made to order pieces with a quick turnaround and competitive prices.

When I first heard of MADE, I was instantly intrigued—I am always hunting for a minimalist, durable hardshell ski jacket with a long, roomy fit. The idea of choosing my features and silhouette is appealing for obvious reasons. As someone who has never struggled to find well fitting clothes, the custom fit selling point was a bit less exciting for me. For folks who have struggled to find well fitting outerwear, MADE could be a real game changer.

In addition to the fit and features, made to order outerwear has an environmental benefit as well. Think of the normal pre-consumer path of a ski jacket:

- Brand X buys large quantity of fabric and materials.

- Materials go to factory where a large batch of jackets are made—this number is based on complex market forecasting.

- Jackets are packed into poly bags and sent to warehouses/distributors throughout the world.

- Jackets are distributed to shops or perhaps directly to consumers

- Unsold jackets are either discounted, or thrown away, along with excess fabric and trims.

Compare this with a MADE, made to order piece:

- Fabric and trims are purchased, often as leftovers from the aforementioned supply chain.

- Consumer orders jacket to their size/specs.

- Jacket is patterned and manufactured in the factory, with ~6 weeks lead time.

- Jacket is packaged in a single layer poly mailer and sent directly to the customer.

With this process, there is no “dead stock”, whether in fabric or garment form. This is significantly less wasteful than the status quo. Additionally, 1-2 packaging and shipping steps are eliminated through this process. With a bit of advanced planning to account for the 6 week lead time, the MADE process has few downsides.

Ordering Process

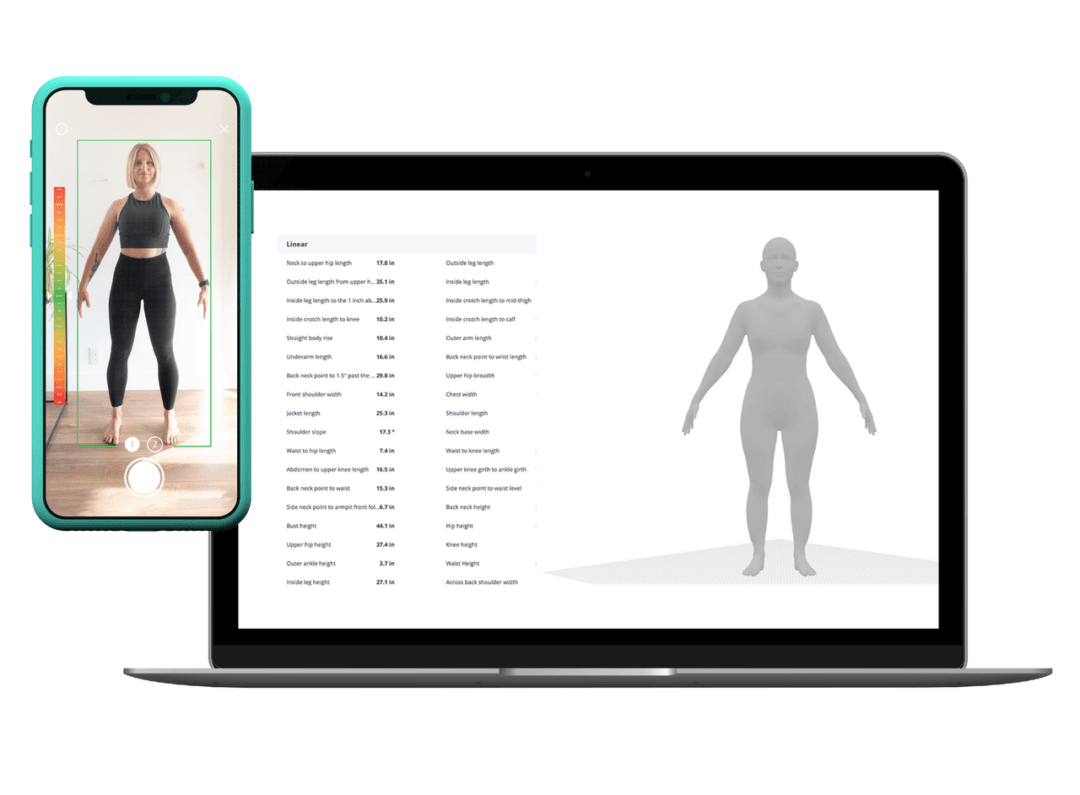

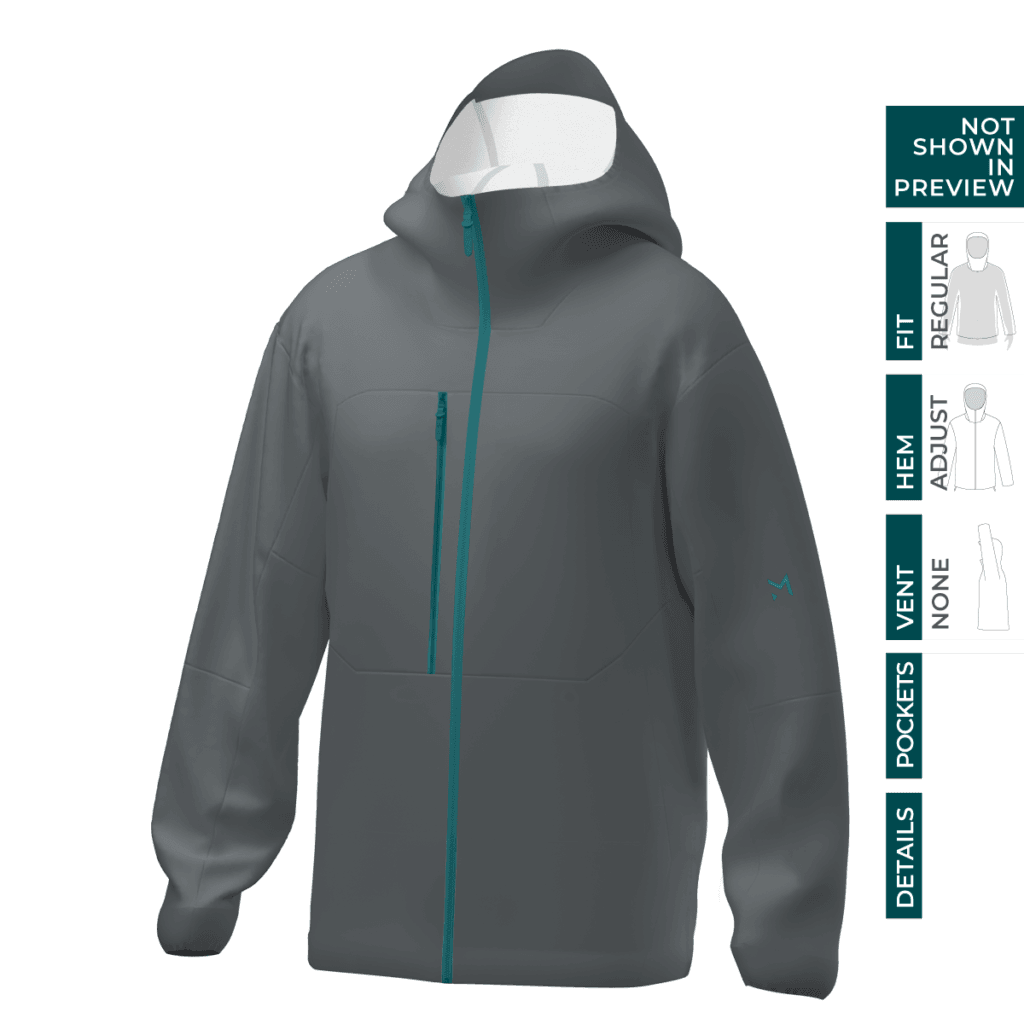

The ordering process, online only, was straightforward. After choosing the Jacket, a customization tool launched. I chose Grey Polartec Neoshell fabric, a dark teal one way full zip, a lightweight hood and cuffs, adjustable hem, past the hips length, and a single chest pocket. This all came out to $615—quite competitive in a world where $700 Arc’teryx shells rule. Next, you send a link to your phone to take front on and side view photos of yourself, wearing tight fitting clothes or long underwear. An AI based software takes 75 measurements of your body. The whole process was quick and easy.

My Jacket

I designed my jacket based on the idea that a hard shell jacket is a fairly specific item in my layering system. When I bring a shell ski touring, it’s usually snowing, wet, deep powder, or very windy. The shell spends most of the day in my pack, coming out for especially exposed or cold sections of a climb, then while skiing down. With this in mind, I went for mostly lightweight fabric and features—like the simple hood and cuffs. I added a single chest pocket, which is nice for a phone or goggle bag, and a long hem that sits below my butt and has adjustable cinches—great for sealing out powder and drafts.

I opted for the Polartec Neoshell fabric—for those who remember the hype around North Face Futurelight technology a few years back, Neoshell uses similar Electrospun PU membrane technology. As with Futurelight, Neoshell prioritizes breathability over absolute waterproofness. In practice, the jacket is plenty waterproof for all below freezing winter applications, and I haven’t had any issues using it as a rain shell in summer downpours either. As an air permeable membrane, it is not windproof like Gore-Tex, but for most ski touring, the wind protection is completely adequate.

The finished weight of my shell is 350g. I am generally a mens large in other brands, for context. To compare with a few other shells in my closet, all sizes are large (yeah… I have too many shells right now)

-Homemade shell using 6d Wp/b fabric – 113g

-Arc’teryx Alpha SL (Anorak) – 228g

-Strafe Cham Anorak – 324g

-Arc’teryx Alpha FL (2017) – 344g

-MADE Hardshell – 349g

-Arc’teryx Beta Long – 470g

In many ways, this shell is an amalgamation of my favorite parts of all of the above jackets. By combining the silhouette of the Beta Long, most of the feature set of the Alpha FL, and (something similar to) the soft and breathable fabric of the Cham, I ended up with pretty darn close to my perfect skiing shell.

Review

I received my jacket early winter 2022, just in time for some wet runs and chilly/snowy ski tours. MADE had some delays getting their production up and running due to supply chain issues (zippers were hard to come by for a while after Covid, I had similar issues with pack zippers). As advertised, the jacket shipped directly from the factory, and only had a poly mailer for packaging, no excess packaging or plastic!

Fit

First thing out of the box, the fit is absolutely excellent. My Arc’teryx shells fit really well, but there is another step up here—the sleeve length is perfect as to never expose my wrists, the extended hem sits right at my crotch, and everything drapes perfectly—like a custom suit (I imagine). I had some questions and concerns going in, regarding the “performance” of the patterning. I’ve always theorized that for average bodies, excellent patterning is often perceived as a good fit, that’s why a brand like Arc’teryx can be widely known as fitting well among folks with different body shapes, to a degree. To maintain this patterning performance over each piece, MADE has six pattern blocks that they work from, essentially a starting point that, based on the measurements of each person, they choose one of these blocks to start with and adjust. In practice, this makes for pieces that not only fit well to each user’s measurements, move with you without restricting or constraining motion. The only place that my jacket didn’t match or exceed the patterning performance of my Arc’teryx Alpha shells was raising my arms high above my head—I had a bit more hem lifting with the MADE shell. This is understandable given the climbing specificity of the Arc’teryx pieces, and the extra length on the MADE shell meant it didn’t pull out of my harness like a shorter shell might.

Fabric and Finish

The Polartec Neoshell fabric is excellent. On a scale of “hardness”, it’s right in the middle between the crinkly shield of armor that is Gore—although perhaps this isn’t the shell I would take somewhere like the Andes when cold, extreme winds are guaranteed.

The construction quality is top notch. Given that ⅔ of the founders of MADE came from Arc’teryx, it shouldn’t be a surprise that they come to the table with significant expertise in shell construction. The seam allowances are a touch larger, and subsequently the seam tape a bit wider, than the my Gore-Tex Pro shells, but very similar to the Strafe shell (and much better than my homemade shell). The stiff hand of the Gore-Tex makes seam taping look super crisp, while the soft and stretchy Neoshell ends up with a few small wrinkles and air pockets.

I had an issue early on with the TPU zipper pull on the main zip, it was a bit too stretchy to feel like a solid pull, and after a few weeks it tore off. It was easy enough to replace with cord, and there is still a metal pull tab so it wasn’t a significant failure. The zippers themselves are in line with industry standards, with YKK Vislon #5 for the main zip and Aquaguard #3 for the pocket zips.

Lessons Learned With My First Custom Jacket

This is more a reflection of my own decisions with only a few nitpicks for MADE. First, I went for a right hand chest pocket. After reading a Colin Haley piece on layering where he complains about all chest pockets being on the left, I wanted to try a right hand option. Turns out, as a right hand dominant human, a right hand chest pocket is pretty awkward for me in practice. Frankly, I may skip the chest pocket altogether if I could do it again—I have plenty of pockets on the layers I’m normally wearing beneath my shell. Speaking of pockets, I would suggest MADE change their zipper pulls for something stiffer and more durable.

The lightweight hood is great, and still has a halo adjustment to be snug enough without a helmet, or fit over a helmet. The hood/neck area isn’t quite roomy enough to pull the hood over a helmet while fully zipped—that seems fine as sometimes jackets with that much space feel oversized and lacking in face protection. I’m not sure I would choose the lightweight cuff again—this depends a lot on glove choice, but with my go-to Arc’teryx Venta AR, it was hard to seal things up well, velcro cuffs next time.

I can’t recommend the past the hips length highly enough—having generally used shorter climbing shells for their simple features and light weight, the long shell was a new experience for me and it was life changing, I won’t be going back to hip length shells for powder skiing any time soon.

Conclusions

There is a lot to like here. In a world where the outdoor clothing industry is increasingly interchangeable, both in supply chain and styles, MADE brings something new and innovative with their model. By delivering with a high quality product, the downsides here are minimal while the upsides numerous. The environmental benefits of made-to-order, combined with the guaranteed excellent fit and ability to personally choose each detail is very cool. All this with a competitive cost, the only downside may be the 6 week lead time. Although, in this world of instant gratification, a little planning and patience allows for a welcome deep breath.

Leave a Reply

You must be logged in to post a comment.