Consider this the clarion call for the preseason backcountry gear once-over. It is the pre-season gear check. You might as well make it count now–nobody likes a gear failure. We’ll go in the order of boots, bindings, skis, skins, and poles.

THR Pre-Season Gear Check

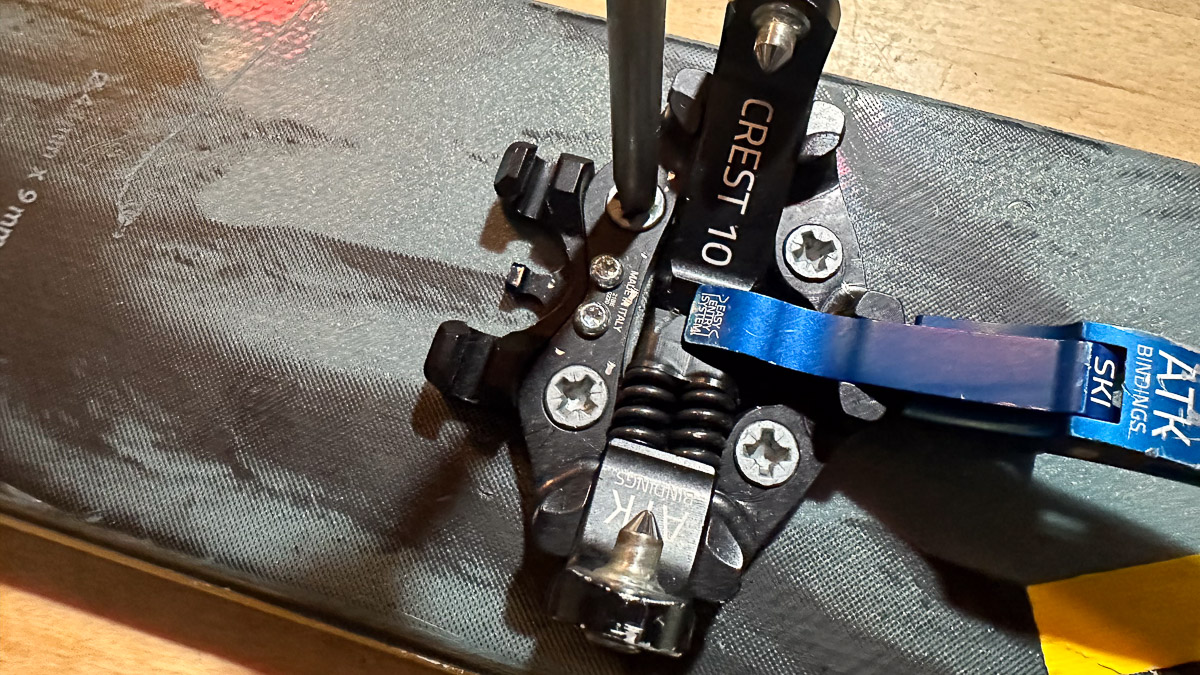

The basics: check all the binding retention screws for tightness. Hand tighten but certainly, don't over tighten.

Help us grow. Share it.

Latest Features

-

Scarpa’s new F1 RS features a BOA H+1 Remote System for the lower and a single buckle + cam-lock powerstrap on the upper. The F1 RS will be the stiffest skiing boot in the F1 line.

First Look: Scarpa’s F1 RS

Scarpa’s F1 gets an overhaul and adds the BOA H+1 System.

-

Winter Wildlands Alliance Policy Director, Anneka Williams. Photo: Jack Stauss

Cutting Through the Noise with the Winter Wildlands Alliance

A conversation with the Winter Wildlands Alliance’s Policy Director, Anneka Williams.

-

Dawn at the Sundeck. Early morning skins are rewarded with quiet slopes and fresh corduroy. Photo: Bryn Brendamour

In Praise of Resort Skinning

Easy access, high reward. When the spigot turns off, the local resort uphill route soothes the mind, builds community, and pumps the blood.